NTT Mould Co., Ltd. established in 2009 in Shenzhen of Guangdong, China, nearby of

Hong Kong. We specialize in high-quality plastic injection molds,

injection molding & part assemblies, also related value-adding

services.

We have applied ISO9001 certification, we strictly comply with ISO

9001 on quality system to every process of design, production and

inspection.

German Precision, American Service, Chinese prices...That's NTT

What NTT serve?

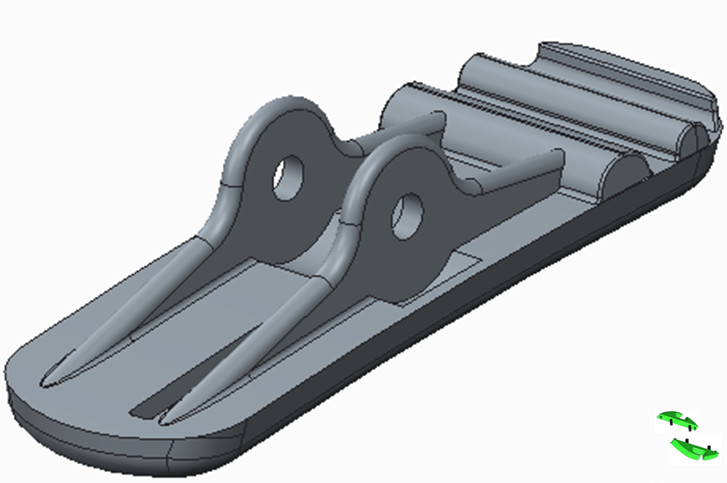

1. High quality & precision injection molds. Hot runner mold, over mold, two-shot mold, unscrewing mold,

multi-cavity mold, etc.

2. Injection molding, part assemblies

3. Value-adding services: Die casting, Painting, Pad-printing, Silk-Screen Printing, Hot

Stamping, Plating, Ultrasonic Welding, Automation.

4. Industries: Automotive, electronics, home & office appliances, medical, etc

5. Markets: 90% molds are exported to North America, South American, Europe

and Australia.

Software we use | 3D Modeling: Pro/ENGINEER , SolidWorks, Unigraphics 2D Drawing: Auto-CAD, E-drawing |

| Qualified suppliers | Mold base and mold steel from LKM, ASSAB, THYSSEN and DAIDO Hot runner system from YUDO, MOLD-MASTER, HASCO, DME, HUSKY. |

Molding Resin experience | ABS, PC, PC+GF, PC/ABS, PBT, PA6+GF, PA66+GF, PPS, PU, PP, PE, TPE,

TPU, LCP, Ultem, etc |

| Our capacity | Build 30 sets molds/month. |

| Minimum tolerance | 0.005mm |

Why you choose NTT?

*** Precision Quality

Specialize in small& medium size molds.

The biggest we can do is about to 1400*1100*1000mm and weight of 10

tons.

Mold tolerance 0.005 mm, Product tolerance 0.05 mm

*** Excellent Service

Our project management team can communicate with customers directly

in written and spoken English. Usually we will reply the emails the

same day and send our offer in 1-2 working days.

*** Competitive Price

Good price with good quality. Our customers will always get what

they pay for.

Where you can find NTT?

1. Our Address: Block A1, Xingfu Lantian technology zone, Tangxia Yong, SongGang

Town, Bao'an district, Shenzhen Guangdong, China 518127

2. FAKUMA 2017, October 17-21, 2017 at Friedrichshafen, Germany.

3. NPE 2018 May 07-11, 2018 at Orlando Florida, USA

You are welcome to visit NTT at any time.